Our economy mobilizes tremendous amounts of resources in the form of materials, labor, machinery, and energy to produce goods and products. At the same time, the lifetime of most of these products has been decreasing, resulting in unprecedented amounts of waste and emissions, not only at the products' end-of-life but also throughout the value chain. Recognizing that such linear extract-, produce-, consume-, dispose-system cannot exist without breaching critical system boundaries, large resources are mobilized to transition towards a Circular Economy (CE) (e.g. The European Green Deal) that aims to preserve the value and functionality of products, parts and materials for a maximum period of time.

Nevertheless, most dominant assessment methods employed to measure the CE transition are based on resource efficiency thinking, which means that in some form, the inputs into an economy, company or process are related to the outputs produced. Yet, the decades of efficiency optimization should raise some doubt whether optimization alone is a necessary condition for reaching absolute system improvements. Pointedly expressed by Peter Drucker that 'there is nothing quite so useless, as doing with great efficiency, something that should not be done at all', it is proposed in the following to assess the effectiveness of a system in preserving functionality first, while only in a second step optimizing the effective systems for efficiency.

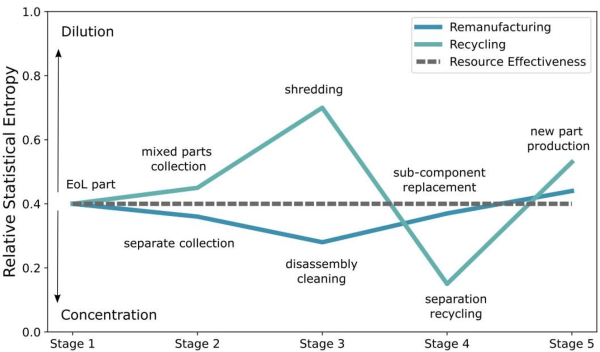

In this context, the basis for evaluating functionality preservation represents the resource-effectiveness metric, which is based on the principle that preservation of functionality avoids dilution, e.g. production of waste, and does not require processes for its restoration, such as sorting, recycling, but also mining, refining and others. The metric employs Statistical Entropy Analysis for quantifying the changes in the distribution of a chosen set of characteristics. In the CE context, the characteristics can be materials, parts, and products, which allows to assess diverse processes and CE strategies, including remanufacturing and recycling systems (see Figure 1). The performance of each system is measured as the distance to the resource-effective system that preserves functionality with minimal efforts (flat dashed line in Figure 1). It is important to note that the resource effectiveness perspective does not focus on how the efforts (changes in Statistical Entropy) are achieved, e.g. sorting by hand or by an automated process, but only on whether the process is effective in reducing the distance to the target state, which makes it complementary to resource efficiency assessments (e.g. life-cycle analysis, cost-benefit-analysis).

Figure 1: Performance of a remanufacturing and a recycling system compared to a resource-effective system that preserves functionality (dashed line).

For more information, contact Alexej Parchomenko (Alexej.parchomenko [at] vito.be (Alexej[dot]parchomenko[at]vito[dot]be))

References:

- Parchomenko, A., et al., 2019, ‘Measuring the circular economy — A multiple correspondence analysis of 63 metrics’, Journal of Cleaner Production 210, pp. 200-216 (DOI: 10.1016/j.jclepro.2018.10.357).

- Parchomenko, A., et al., 2020, ‘Evaluation of the resource effectiveness of circular economy strategies through multilevel Statistical Entropy Analysis’, Resources, Conservation and Recycling 161, p. 104925 (DOI: 10.1016/j.resconrec.2020.104925).

- Parchomenko, A., et al., 2021, ‘Resource effectiveness of the European automotive sector – a statistical entropy analysis over time’, Resources, Conservation and Recycling 169, p. 105558 (DOI: 10.1016/j.resconrec.2021.105558).